The 21 circuit wiring harness is a comprehensive electrical system designed for modern vehicles, offering organized and efficient power distribution. It features high-quality, color-coded wires, labeled for easy identification, ensuring a streamlined installation process. This universal harness is compatible with various automotive applications, making it ideal for custom builds and restorations.

1.1 Overview of the Wiring Harness

The 21 circuit wiring harness is a pre-assembled electrical system designed to simplify vehicle wiring. It includes a fuse block, color-coded wires, and labeled connections for easy identification. The harness is universally compatible with GM, Ford, and Chrysler vehicles, making it ideal for hot rods, restorations, and custom builds. Its organized design reduces clutter and ensures reliable power distribution.

The 21 circuit system is crucial for modern vehicles, providing a robust and organized electrical framework. It supports advanced components like power windows, ABS, and infotainment systems. The color-coded wires and labeled connections ensure easy troubleshooting and customization. This system is essential for maintaining reliability and safety in complex automotive electrical setups, making it a cornerstone of vehicle wiring. The 21 circuit harness includes a central fuse block, color-coded wires with labels, and high-quality connectors. These components ensure reliable power distribution and easy troubleshooting.

The fuse block serves as the central power distribution hub, housing 18 fuses to protect individual circuits. It organizes wires into sections, simplifying installation and maintenance. Each fuse corresponds to specific vehicle functions, ensuring safety and preventing overloading. The block’s design allows for easy access and replacement of fuses, enhancing reliability and reducing downtime. The 21 circuit wiring harness features universally color-coded wires, ensuring easy identification and installation. Wires are labeled every 5 inches, providing clear guidance for their specific functions. This labeling system helps organize the wiring layout, reduces confusion, and streamlines the installation process. The color-coding and labeling are designed to meet universal automotive standards, making the harness adaptable to various vehicle applications. The 21 circuit wiring harness includes high-quality connectors and terminals, ensuring secure and reliable connections; These components are designed for durability, with weather-resistant materials to withstand harsh environments. Connectors are clearly marked, and terminals are securely crimped or soldered for optimal conductivity. The connectors and terminals are compatible with various automotive applications, making installation straightforward and efficient. Preparing the 21 circuit wiring harness involves unpacking and inspecting all components for damage. Organize wires into logical sections based on the wiring diagram for a systematic installation process. When unpacking the 21 circuit wiring harness, carefully inspect each component for any signs of damage or wear. Ensure all wires are securely connected and properly labeled. Check the fuse block, connectors, and terminals for integrity. Verify that all necessary components, such as cable ties and wiring diagrams, are included. This step ensures a smooth installation process and prevents future issues. Start by organizing the wires into logical sections based on their intended use. Use cable ties to secure and group them neatly. Begin with the largest coil of wires and work your way through smaller sections. Refer to the wiring diagram to ensure proper routing and connections. This systematic approach prevents tangles and simplifies the installation process, reducing the risk of errors. Essential tools include wire cutters, strippers, and a multimeter. Materials like cable ties, heat shrink tubing, and connectors are necessary. Safety gear such as gloves and goggles is recommended.

The installation requires a set of basic tools, including wire cutters, strippers, and crimpers. A multimeter is crucial for testing continuity and voltage. Pliers and screwdrivers are needed for connectors and fuse block connections. Heat guns can be used for heat shrink tubing. Additionally, cable ties and organizing tools help manage the wiring neatly and efficiently. Wear protective gloves and goggles to prevent injury. Ensure the vehicle is disconnected from the battery to avoid live circuits. Use insulated tools to prevent electrical shocks. Avoid testing wires with bare ends, as this can cause short circuits. Never remove the three cable ties closest to the fuse panel, as this could damage the harness. Always ground the system properly and consult a professional if unsure. Start with the largest coil of wires and organize them into sections. Review the wiring worksheet and diagram to identify circuits and components. Use color-coding and labels for quick identification. Avoid removing the three cable ties closest to the fuse panel to prevent damage. Follow the diagram systematically to ensure proper connections. Begin by identifying the main components, such as the fuse block and battery connections. Use the color-coded wires and labels to trace circuits. Refer to the wiring worksheet for a detailed breakdown. Start with the largest coil of wires and organize them into sections. Follow the diagram step-by-step to ensure accurate connections. Avoid removing cable ties near the fuse panel to prevent damage. Carefully map each circuit to its corresponding component using the wiring diagram. Identify power sources, grounds, and connectors. Label each wire based on its function and destination. Organize wires into logical sections, such as lighting, ignition, and accessories. Cross-reference the diagram with the harness to ensure all components are accounted for. This systematic approach ensures a smooth installation process. Common errors include incorrect wire connections, ignoring safety protocols, and removing essential cable ties. These mistakes can lead to system malfunctions or electrical damage. Incorrect wire connections are a prevalent issue, often due to disregarding color-coding or labels. Always cross-reference the wiring diagram to ensure proper connections. Mixing up wires can lead to malfunctions or electrical damage. Double-check each connection before powering up the system to avoid costly repairs or safety hazards. Patience and attention to detail are crucial in this step. Ignoring safety protocols is a critical mistake that can lead to electrical shocks, short circuits, or even fires. Always disconnect the battery before starting work to prevent live currents. Wear protective gear, such as gloves and safety glasses, to minimize risks. Skipping these steps can result in severe injuries or irreversible damage to the wiring system and vehicle components. Safety must always come first. Troubleshooting involves identifying and resolving issues systematically. Use a multimeter to check for continuity, voltage drops, and short circuits. Consult the wiring diagram to trace circuits and verify connections. Identifying circuit issues begins with a visual inspection for damaged wires or connectors. Use a multimeter to test continuity and voltage, ensuring each circuit functions correctly. Refer to the wiring diagram to map connections and isolate faulty sections. Common problems include short circuits, open circuits, or incorrect wire connections. Systematically testing each circuit helps pinpoint issues efficiently. A multimeter is essential for diagnosing electrical issues in a 21 circuit wiring harness. Set it to DC volts to measure voltage drops or check power supply. Use the resistance setting to test for short circuits or open wires. Continuity mode helps verify connections. Always reference the wiring diagram to identify expected readings and isolate faults efficiently. The 21 circuit wiring harness allows for customization to meet specific vehicle needs. Evaluate your application to determine necessary modifications. Use wiring diagrams to guide adaptations. Modifying the 21 circuit wiring harness for specific needs requires careful planning. Identify the circuits that need adjustment based on your vehicle’s requirements. Use the provided wiring diagram to locate relevant wires and connectors. For example, adding aftermarket components like a stereo system may require rerouting or splicing specific wires. Always ensure connections are secure and properly insulated to prevent electrical issues. Additionally, label any modified wires to maintain clarity for future maintenance or upgrades. This approach ensures the harness remains reliable and tailored to your vehicle’s unique setup, enhancing overall performance and functionality. Regularly review the modifications to ensure compliance with safety standards and avoid potential risks. By following these steps, you can customize the harness effectively while maintaining its integrity. When adding or removing components from the 21 circuit wiring harness, ensure modifications align with your vehicle’s electrical requirements. Use the wiring diagram to identify relevant circuits and connectors. Label new wires clearly and test connections to avoid malfunctions. For additions like stereo systems, verify compatibility and follow manufacturer instructions. Always retain the original harness for unique connectors, ensuring future adaptability and minimizing potential issues. Manufacturers provide extensive resources, including detailed wiring diagrams and troubleshooting guides, to assist with the 21 circuit wiring harness installation and customization. Utilize these materials for a seamless experience. The user manual is an essential resource for installing the 21 circuit wiring harness. It provides detailed diagrams, step-by-step instructions, and troubleshooting tips. Review it thoroughly to understand component functions, safety precautions, and wiring layouts. This guide ensures a smooth installation process by addressing common questions and offering solutions for custom configurations and repairs. When facing complex issues or custom configurations, consulting with experts is crucial. Manufacturer support teams and experienced installers can provide tailored guidance. Join online forums or contact technical support for troubleshooting and advice. Don’t hesitate to seek help for specific wiring challenges, ensuring your harness is installed safely and efficiently. Conduct a systematic inspection of all connections and circuits. Use a multimeter to verify continuity and voltage. Ensure every component functions correctly before finalizing the installation. After installation, systematically test each component by turning them on individually. Verify lights, gauges, and electronic systems function correctly. Use a multimeter to check circuit continuity and voltage levels. Ensure all fuses are intact and properly seated. Test inputs like sensors and switches to confirm they trigger corresponding outputs. This step ensures every part of the harness operates as intended. Completing the 21 circuit wiring harness installation ensures a reliable electrical system. Regular maintenance and inspections are crucial for long-term functionality. Consult your manual for future upgrades and troubleshooting. The 21 circuit wiring harness offers a high-quality, organized solution for vehicle electrical systems. It features color-coded, labeled wires and a robust fuse block for efficient power distribution. Proper installation, following the wiring diagram, and regular maintenance ensure reliability. Consulting the user manual and manufacturer support are essential for troubleshooting and customization. Regularly inspect wires for wear or damage and clean connections to ensure optimal performance. Use a multimeter to check for continuity and voltage drops. Organize wires neatly to prevent tangling and damage. Consult the user manual for specific maintenance recommendations and reach out to manufacturer support for guidance. 1.2 Importance of the 21 Circuit System

Key Components of the 21 Circuit Harness

2.1 Fuse Block and Its Function

2.2 Wires: Color-Coding and Labeling

2.3 Connectors and Terminals

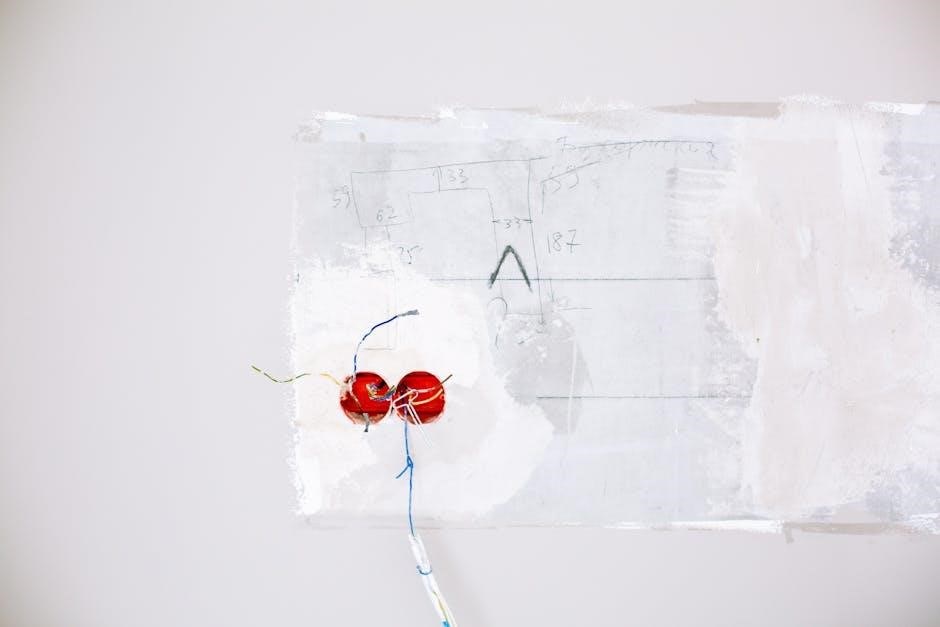

Preparation for Installation

3.1 Unpacking and Initial Inspection

3.2 Organizing Wires and Sections

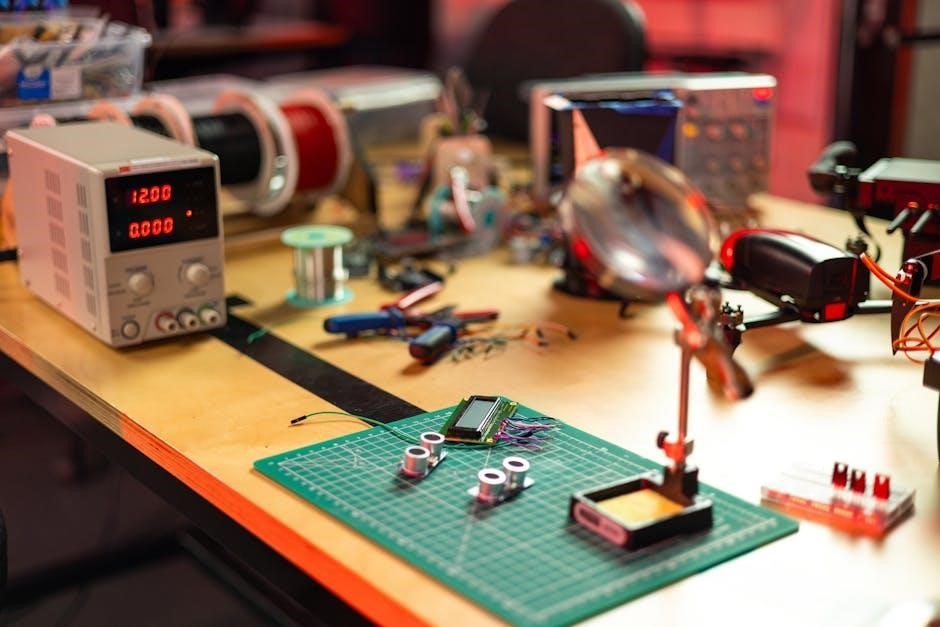

Tools and Materials Needed

4.1 Essential Tools for Installation

4.2 Safety Equipment and Precautions

Understanding the Wiring Diagram

5.1 Reading the Diagram

5.2 Mapping Circuits and Components

Common Mistakes to Avoid

6.1 Incorrect Wire Connections

6.2 Ignoring Safety Protocols

Troubleshooting Techniques

7.1 Identifying Circuit Issues

7.2 Using a Multimeter Effectively

Customization and Adaptation

8.1 Modifying for Specific Needs

8.2 Adding or Removing Components

Manufacturer Support and Resources

9.1 Consulting the User Manual

9.2 Reaching Out to Experts

Final Testing and Inspection

10.1 Systematic Testing Process

10.2 Ensuring All Components Function

11.1 Summary of Key Points

11.2 Future Maintenance Tips