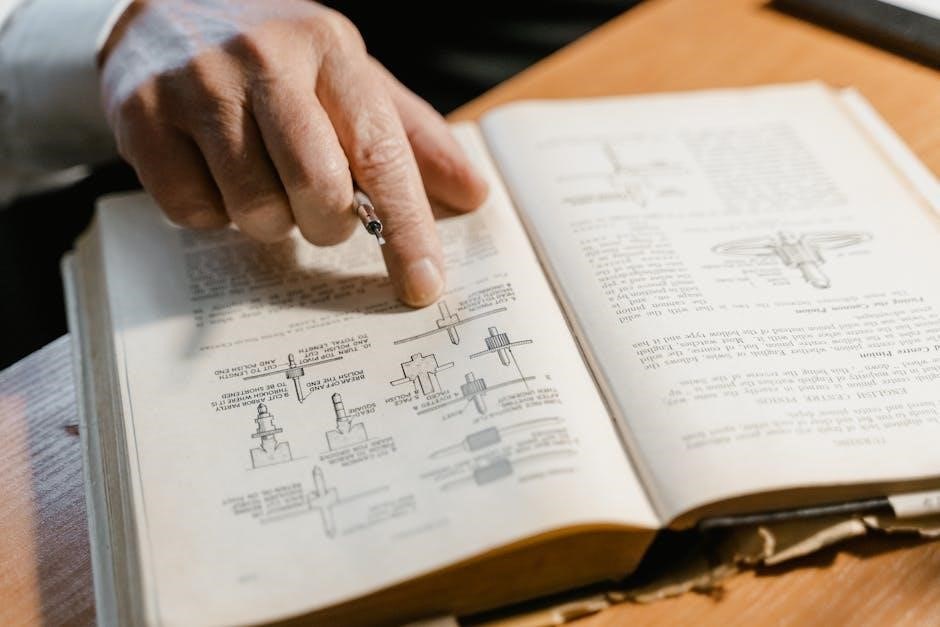

A 6-speed manual transmission diagram illustrates the mechanical layout of gears, shafts, and components. It helps understand how power flows through the gearbox, enabling smooth gear shifts.

1.1 Overview of Manual Transmissions

A manual transmission is a type of gearbox that requires the driver to manually change gears using a clutch pedal and gearshift. It typically features multiple gear ratios, such as a 6-speed setup, allowing for precise control over power delivery. Unlike automatic transmissions, manuals rely on driver input to engage and disengage gears, offering enhanced driver involvement and often better fuel efficiency. The mechanical simplicity of manual transmissions makes them lighter and more cost-effective, contributing to their popularity in various vehicles. Understanding their operation is essential for optimizing performance and longevity.

1.2 Importance of Understanding Transmission Diagrams

Understanding transmission diagrams is crucial for diagnosing issues, performing repairs, and optimizing performance. These diagrams provide a visual representation of the mechanical components, such as gears, shafts, and linkages, allowing for better comprehension of how the system operates. By studying the layout, technicians can identify worn or damaged parts and ensure proper reassembly. For enthusiasts, it enhances troubleshooting and maintenance skills. Additionally, diagrams are essential for educational purposes, helping students and engineers grasp the complexities of 6-speed manual transmissions. This knowledge enables more efficient repairs and improves overall vehicle performance. Accurate diagrams are indispensable for both professionals and hobbyists.

Structure of a 6-Speed Manual Transmission

The structure includes gear trains, shafts, and bearings, precisely mounted for efficient power transmission. These components work together to support the transmission’s operational demands.

2.1 Gear Train and Shaft Components

The gear train in a 6-speed manual transmission consists of multiple gears arranged to provide six forward speeds and one reverse. Input and output shafts are central, with gears mounted on them. These gears are paired to create different speed ratios. The gear train includes a reverse idler gear and a final drive gear. Shaft components like splined sections ensure proper gear engagement. Bearings and mounts support the shafts, reducing friction and ensuring smooth operation. The arrangement of gears and shafts is carefully designed to optimize power transmission and efficiency across all speed ranges.

2.2 Bearings and Mounting Elements

Bearings and mounting elements are critical in a 6-speed manual transmission. Taper roller bearings reduce friction and support gear shafts, ensuring smooth rotation. Snap rings and straight pins secure components, preventing movement. These elements are essential for maintaining transmission stability and durability, allowing gears to engage seamlessly. Proper lubrication of bearings is vital to prevent wear and overheating, ensuring optimal performance. Mounting elements like bushings and sleeves align components accurately, while hydraulic systems assist in gear engagement. Together, they ensure efficient power transfer and minimize mechanical stress.

Key Components of the 6-Speed Manual Transmission

- Gear train: Includes multiple gears and shafts that transmit power through different ratios.

- Bearings: Essential for smooth operation, reducing friction between moving parts.

- Synchronizers: Ensure smooth gear engagement by equalizing speed between gears.

3.1 Input and Output Shafts

The input shaft and output shaft are critical components in a 6-speed manual transmission. The input shaft connects to the clutch and engine, transmitting power into the gearbox. The output shaft sends power to the driveshaft, propelling the vehicle. Both shafts are supported by bearings to ensure smooth operation. The input shaft typically features splines to engage with the clutch, while the output shaft connects to the final drive system. Proper alignment and lubrication of these shafts are essential for efficient power transmission and longevity of the transmission system.

3.2 Gear Selector Mechanism

The gear selector mechanism in a 6-speed manual transmission enables the driver to engage specific gears. It consists of a gearshift assembly, linkages, and a detent system. When the driver moves the gearshift, it actuates the selector forks, which slide the synchronizers to engage the desired gear. The mechanism ensures smooth transitions between gears by aligning the selector forks with the gear splines. Proper alignment prevents grinding and ensures efficient power transfer. The detent system provides a tactile feedback, indicating successful gear engagement. This mechanism is critical for precise control over gear selection and optimal vehicle performance.

3.3 Synchronizers and Clutch System

The synchronizers in a 6-speed manual transmission ensure smooth gear engagement by matching the speed of the gear to the shaft. The clutch system, including the clutch pedal and hydraulic components, temporarily disconnects the engine from the transmission during shifts. This allows seamless gear transitions without grinding or damage. Proper synchronization and clutch operation are critical for efficient power transfer and driver control. Regular maintenance, such as inspecting the clutch and synchronizer rings, prevents wear and tear, ensuring optimal performance and longevity of the transmission system.

Shifting Mechanism in a 6-Speed Manual Transmission

The shifting mechanism involves the gearshift assembly and linkages, connecting driver input to the transmission. The clutch pedal and hydraulic system synchronize gear engagement, enabling smooth shifts and precise control.

4.1 Gearshift Assembly and Linkages

The gearshift assembly and linkages are crucial for precise gear selection in a 6-speed manual transmission. The assembly includes the gearshift lever, detent mechanism, and connecting rods. These components work together to engage gears smoothly. The linkages transmit the driver’s input to the transmission, ensuring accurate gear alignment. Proper lubrication and adjustment of these parts are essential for optimal performance. Wear or misalignment can lead to gear engagement issues, emphasizing the importance of regular maintenance; The system’s reliability directly impacts the driving experience, making it a key focus in transmission design and functionality.

4.2 Clutch Pedal and Hydraulic System

The clutch pedal and its associated hydraulic system are critical for smooth gear engagement in a 6-speed manual transmission. The pedal connects to a master cylinder, which presses the clutch disc against the flywheel via hydraulic pressure. This disengages the engine from the transmission, allowing seamless gear shifts. The system relies on hydraulic fluid to maintain consistent pressure. Over time, the hydraulic system may require bleeding to remove air bubbles, ensuring precise clutch engagement. Regular inspection of the clutch pedal’s free play and the hydraulic lines is essential to prevent wear and tear. Proper maintenance ensures optimal performance and longevity of the system.

How a 6-Speed Manual Transmission Works

The process involves selecting gears via the clutch and gearshift, disengaging one gear and engaging another to transfer power through the transmission’s shafts and gears efficiently.

5.1 Gear Selection Process

The gear selection process in a 6-speed manual transmission involves coordinating the clutch pedal, gearshift, and synchronizers. The driver presses the clutch pedal, disengaging the engine from the transmission. Using the gearshift, they select the desired gear by moving the shift fork, which engages the target gear. Synchronizers ensure smooth gear engagement by matching the speed of the gear to the shaft. This process allows seamless transitions between gears, optimizing power delivery and vehicle control. Proper timing and technique are essential for efficient shifting.

5.2 Power Flow and Torque Transmission

In a 6-speed manual transmission, power flows from the engine through the input shaft to the gear train. The engaged gear pair transfers torque to the output shaft, which connects to the drivetrain. When a gear is selected, the clutch disengages, and the synchronizer aligns the gear with the shaft speed. Once engaged, the clutch reconnects, transmitting power smoothly. This process ensures efficient torque delivery, with each gear ratio optimized for specific driving conditions, enhancing both performance and fuel efficiency. The diagram illustrates this flow, showing how power transitions through the gearbox to the wheels.

Advantages of a 6-Speed Manual Transmission

A 6-speed manual transmission offers improved fuel efficiency and enhanced driver control. It provides better torque management and a more engaging driving experience compared to automatic systems.

6.1 Improved Fuel Efficiency

A 6-speed manual transmission enhances fuel efficiency by allowing precise control over gear shifts. Drivers can optimize engine RPMs for specific driving conditions, reducing unnecessary fuel consumption. Unlike automatic transmissions, manuals eliminate torque converter losses, directly transferring power to the wheels. This mechanical efficiency results in better mileage, especially in city driving. Additionally, the ability to downshift before braking reduces wear on the braking system, further improving overall efficiency. Modern designs also feature optimized gear ratios, ensuring smoother power delivery while minimizing fuel waste. This makes manual transmissions a preferred choice for eco-conscious and performance-oriented drivers alike.

6.2 Enhanced Driver Control

A 6-speed manual transmission offers drivers precise control over gear shifts, enabling better acceleration and performance. By manually selecting gears, drivers can optimize power delivery and torque output, especially in dynamic driving conditions. This direct connection between the driver and the vehicle enhances the driving experience, providing a sense of engagement and responsiveness. The ability to choose the right gear at the right time allows for smoother transitions and improved handling, making it ideal for both everyday commuting and spirited driving. This level of control is a key advantage of manual transmissions over automatic systems.

Maintenance and Repair of a 6-Speed Manual Transmission

Regular lubrication and inspection of gears, bearings, and the clutch system are essential. Replacing worn components and addressing corrosion prevents premature wear and ensures smooth operation.

7.1 Regular Inspection and Lubrication

Regular inspection of the 6-speed manual transmission ensures optimal performance and prevents premature wear. Check the gear oil level and top it off as needed to maintain proper lubrication. Inspect the transmission case for leaks and damage. Examine the gear shafts and bearings for signs of wear or corrosion. Lubricate all moving parts, including the synchromesh gears and selector forks, to ensure smooth shifting. Replace the transmission fluid every 30,000 to 60,000 miles, depending on usage. Regular maintenance extends the lifespan of the transmission and prevents costly repairs.

7.2 Common Issues and Troubleshooting

Common issues with 6-speed manual transmissions include worn clutch components, synchronizer damage, and gear grinding. Troubleshooting often involves inspecting the clutch pedal, checking transmission fluid levels, and ensuring proper gear engagement.

- Clutch wear: Leads to slipping or failure to engage gears.

- Synchronizer issues: Cause difficulty shifting into specific gears.

- Fluid leaks: Can result from damaged seals or gaskets.

Regular inspections and timely repairs are crucial to prevent further damage and ensure smooth operation.

A 6-speed manual transmission diagram provides a clear understanding of gear interactions and mechanical components. It highlights the benefits of manual transmissions, such as improved fuel efficiency and driver control.

8.1 Summary of Key Points

The 6-speed manual transmission diagram provides a detailed overview of the gearbox’s internal structure, including gears, shafts, and synchronizers. It highlights the mechanical components and their interactions, such as the gear selector mechanism and clutch system. Understanding this diagram is essential for diagnosing issues and performing repairs. The transmission’s design emphasizes efficiency and control, making it a popular choice for drivers seeking precise gear shifts. Regular maintenance, like lubrication and inspections, ensures optimal performance and longevity. This overview serves as a foundation for deeper exploration of the transmission’s functionality and troubleshooting.