Manual handling regulations are critically designed to ensure the safety and well-being of all individuals in the workplace, whether they are directly engaged.

Injuries, particularly to the back, shoulders, and neck, significantly contribute to sickness absence; those unaccustomed to such tasks are most at risk.

This guidance helps minimize injury risks when lifting or carrying heavy/awkward equipment, or performing repetitive lifting tasks, crucial for workplace safety.

Overview of Manual Handling Risks

Manual handling risks encompass a broad spectrum of potential injuries, prominently affecting the back, shoulders, and neck, leading to significant workplace absences.

These risks are heightened for individuals not regularly involved in such tasks, emphasizing the importance of proper training and awareness. Hazards arise from lifting or carrying heavy, awkwardly shaped, or unstable loads.

Repetitive movements, forceful exertions, and awkward postures further exacerbate these risks. Insufficient training, poor workstation design, and inadequate risk assessments contribute to increased injury rates.

Ignoring these factors can lead to musculoskeletal disorders (MSDs), impacting employee health and productivity. Proactive identification and mitigation of these risks are paramount for a safe working environment.

Effective control measures, as outlined in regulations, are essential to minimize these hazards and protect workers;

Significance of Manual Handling Injuries

Manual handling injuries carry substantial significance, extending beyond individual suffering to impact organizational productivity and costs. They are a major contributor to reported workplace illnesses and sickness absence statistics.

These injuries often result in prolonged pain, reduced mobility, and the need for medical intervention, including physiotherapy and, in severe cases, surgery. The financial burden includes compensation claims, healthcare expenses, and lost work time.

Furthermore, injuries can negatively affect employee morale and job satisfaction. Addressing these risks proactively demonstrates a commitment to employee well-being.

Effective risk management and adherence to regulations like MHOR 1992 are crucial for minimizing these impacts and fostering a healthier, more productive workforce.

Ignoring the significance of these injuries can lead to legal repercussions and damage to an organization’s reputation.

The Manual Handling Operations Regulations 1992 (MHOR)

MHOR 1992 mandates employers ensure employees understand risks during hazardous manual handling tasks, requiring compliance with safety regulations for workplace well-being.

Key Requirements of MHOR

MHOR places a clear duty on employers to avoid, so far as reasonably practicable, risks from manual handling operations. This begins with a thorough risk assessment, identifying hazardous tasks and evaluating the factors contributing to potential harm.

Employers must ensure employees are provided with adequate information, instruction, and training regarding safe manual handling techniques. This includes demonstrating proper lifting and carrying methods, and awareness of potential musculoskeletal disorders.

Furthermore, MHOR requires employers to implement control measures to reduce risks, prioritizing elimination or reduction of the handling task itself. Where handling is unavoidable, engineering controls, organizational changes, and personal protective equipment should be considered, following a hierarchy of control.

Regular review of risk assessments and training programs is essential to maintain effectiveness and adapt to changing work practices. Compliance with MHOR is paramount for protecting employee health and minimizing workplace injuries.

Employer Responsibilities under MHOR

Employers bear the primary responsibility for ensuring employee safety regarding manual handling, as outlined in the Manual Handling Operations Regulations 1992 (MHOR). This encompasses a proactive approach to risk management, starting with comprehensive risk assessments of all tasks involving manual handling.

Crucially, employers must ensure employees fully understand the risks present during hazardous tasks. This necessitates providing clear information, instruction, and tailored training programs on safe handling techniques. Employers are also obligated to consider the employee’s state of health.

Furthermore, employers must implement appropriate control measures, prioritizing elimination or reduction of risks. Regular reviews of assessments and training are vital, alongside adherence to amendments like the Health and Safety (Miscellaneous Amendments) Regulations.

Employee Responsibilities under MHOR

Employees, while supported by employer provisions, also hold key responsibilities under the Manual Handling Operations Regulations 1992 (MHOR). Individuals must cooperate fully with their employer regarding health and safety measures, including actively participating in risk assessments and training programs.

It is essential to follow the training received and utilize the safe handling techniques instructed. Employees are obligated to report any hazardous situations or potential risks identified during manual handling tasks immediately to their supervisor.

Furthermore, employees must inform their employer of any pre-existing health conditions that may be aggravated by manual handling work. A commitment to safe practices and open communication is vital for maintaining a secure working environment.

Risk Assessment for Manual Handling

The risk assessment of manual handling considers the employee’s state of health and the risks to their health arising from the work performed.

Identifying hazardous tasks and assessing risks are vital, considering factors to implement effective control measures for a safer workplace.

Identifying Hazardous Manual Handling Tasks

Identifying tasks posing manual handling risks is the foundational step in ensuring workplace safety. This involves a thorough review of all job roles and activities where employees might lift, carry, push, pull, or otherwise manipulate objects.

Specifically, focus on tasks involving heavy or awkwardly shaped items, repetitive movements, or those requiring excessive force. Consider situations with poor posture, long carrying distances, or unstable loads.

Tasks that aren’t routinely performed, or those involving unloading or loading, often present heightened risks. Observing employees performing these tasks and consulting with them directly can reveal hidden hazards. Remember, injuries often stem from tasks employees aren’t adequately prepared for.

Assessing Risks: Factors to Consider

Risk assessment demands a detailed examination of several factors. The weight of the load is paramount, but consider also the distance it must be carried, the height at which it’s lifted or placed, and any twisting, bending, or stretching involved.

The individual’s capability is crucial; assess employee health, experience, and training. A worker’s pre-existing health conditions must be considered, impacting their suitability for certain tasks.

Environmental factors, like slippery floors, poor lighting, or restricted space, significantly elevate risk. The frequency of the task and the overall work organization also play a role. A comprehensive assessment considers all these elements to determine the level of potential harm.

Control Measures: Hierarchy of Control

Effective control of manual handling risks follows a hierarchy. Firstly, elimination – can the task be removed entirely? If not, substitution should be considered – can a mechanical aid replace manual effort?

Engineering controls, like adjustable work surfaces or lifting equipment, are the next step. Administrative controls involve changing work practices, such as rotating tasks or providing adequate rest breaks.

Finally, personal protective equipment (PPE), like gloves, offers limited protection and should be a last resort. Employers must ensure employees understand these controls and are trained in their proper use, prioritizing prevention over reliance on PPE.

Competency and Training

The Manual Handling Operations Regulations (MHOR) 1992 state that assessors should be competent and have appropriate experience and knowledge for risk assessments.

Training programs are vital, ensuring employees understand risks and safe practices, while refresher courses maintain competency and address legislative updates.

Competent Assessors: Requirements

The Manual Handling Operations Regulations 1992 explicitly state the necessity for competent individuals to conduct manual handling risk assessments. This competency isn’t simply a matter of formal qualifications, though relevant training is crucial.

Assessors must possess appropriate knowledge and practical experience to accurately identify hazardous tasks, evaluate associated risks, and recommend effective control measures. This includes understanding the biomechanical principles of safe lifting and carrying, as well as the potential health effects of poor manual handling practices.

Furthermore, assessors should be familiar with the specific work environment and the tasks performed within it. Ongoing professional development is essential to stay abreast of changes in legislation, best practices, and emerging risks. Documentation of assessor competency is highly recommended, demonstrating a commitment to safety and compliance.

Training Programs for Manual Handling

Effective training programs are fundamental to minimizing manual handling injuries, ensuring employees understand the risks present during hazardous tasks. These programs should cover a range of topics, including proper lifting techniques, safe carrying methods, and the importance of risk assessments.

Training must be tailored to the specific manual handling tasks performed by employees, addressing the unique challenges of their roles. Practical, hands-on exercises are vital, allowing participants to practice safe techniques under supervision. Emphasis should be placed on recognizing risk factors and implementing appropriate control measures.

Programs should also cover employer and employee responsibilities under the Manual Handling Operations Regulations 1992, fostering a culture of safety and shared accountability. Documentation of training completion is essential for demonstrating compliance.

Refresher Training and Updates

Maintaining competency in manual handling requires regular refresher training and updates. Initial training provides a foundation, but practices can degrade over time, and new risks may emerge with changes in tasks or equipment.

Refresher courses should reinforce core principles, address any observed deficiencies in practice, and introduce new guidance or legislative amendments. The frequency of refresher training should be determined by risk assessment, but generally, annual updates are recommended.

Updates should also reflect any changes to the Manual Handling Operations Regulations 1992, as amended by the Health and Safety (Miscellaneous Amendments) Regulations. Keeping employees informed about the current state of legislation is crucial for ongoing compliance and a safe working environment.

Specific Regulations & Amendments

Employers must comply with the Manual Handling Operations Regulations 1992, as amended by the Health and Safety (Miscellaneous Amendments) Regulations, ensuring safety.

Newly-published European Commission legislation regulates ground-handling operations for the first time, emphasizing compliance with safety standards and regulations.

Health and Safety (Miscellaneous Amendments) Regulations Impact

The Health and Safety (Miscellaneous Amendments) Regulations significantly impact manual handling by reinforcing employer duties under the Manual Handling Operations Regulations 1992 (MHOR). These amendments clarify and strengthen existing requirements, ensuring a more robust framework for protecting employees.

Specifically, the amendments address areas like risk assessment methodologies and the provision of information, instruction, and training. Employers are now explicitly required to review and update risk assessments regularly, considering the state of health of their workforce.

Furthermore, the regulations emphasize the importance of considering pre-existing health conditions when assigning manual handling tasks. This holistic approach aims to prevent exacerbation of existing injuries or health issues. Compliance with these amendments is crucial for maintaining a safe working environment and avoiding potential legal repercussions.

European Commission Legislation on Ground-Handling Operations

Newly-published European Commission legislation, coming into force this month, establishes regulations for ground-handling operations for the first time, directly impacting manual handling practices within the aviation sector.

These regulations prioritize worker safety by setting stringent standards for lifting, carrying, and maneuvering luggage and cargo. Compliance with these new rules is paramount for airport operators and ground handling service providers.

The legislation focuses on minimizing risks associated with repetitive movements, awkward postures, and heavy loads, common in ground handling. It mandates comprehensive risk assessments and the implementation of appropriate control measures, including ergonomic equipment and optimized work procedures. This legislation aims to harmonize safety standards across European airports.

Health Considerations

The risk assessment of manual handling must consider an employee’s state of health, regarding work type and potential risks to their wellbeing.

Employers must assess employee health and suitability for tasks, considering any pre-existing conditions that could be aggravated by physical demands.

Employee Health and Suitability for Tasks

Assessing employee health is paramount when assigning manual handling tasks. Employers are legally obligated to consider an individual’s physical and mental state, ensuring the work aligns with their capabilities.

This involves evaluating pre-existing health conditions – musculoskeletal issues, cardiovascular problems, or pregnancy – that might increase risk. A thorough understanding of the work’s demands, coupled with an employee’s health profile, informs safe task allocation.

Regular health surveillance can identify emerging issues, allowing for adjustments to workload or task design. Prioritizing employee wellbeing isn’t just ethical; it’s a legal requirement under the Manual Handling Operations Regulations 1992, minimizing injury potential and promoting a healthier workforce.

Open communication between employer and employee is vital.

Considering Pre-existing Health Conditions

Careful consideration of pre-existing health conditions is crucial during manual handling risk assessments. Employers must understand how conditions like musculoskeletal disorders, cardiovascular issues, or respiratory problems might be aggravated by physical tasks.

Individuals with such conditions aren’t automatically excluded, but tasks may require modification or avoidance. A confidential dialogue with the employee is essential to gather relevant information and explore reasonable adjustments.

The risk assessment must account for these individual vulnerabilities, ensuring the assigned work doesn’t exacerbate existing health concerns. Prioritizing employee wellbeing and adhering to the MHOR 1992 is paramount, fostering a safe and inclusive work environment.

Ignoring these factors can lead to increased injury risk and legal repercussions.

Practical Guidance for Safe Manual Handling

If your job involves lifting or carrying, understanding proper techniques is vital to minimize injury risk – this guideline should help ensure workplace safety.

Employers must comply with the MHOR 1992, ensuring employees understand risks during hazardous manual handling tasks.

Lifting Techniques

Proper lifting techniques are paramount in preventing manual handling injuries, particularly those affecting the back, shoulders, and neck – a significant cause of workplace absence.

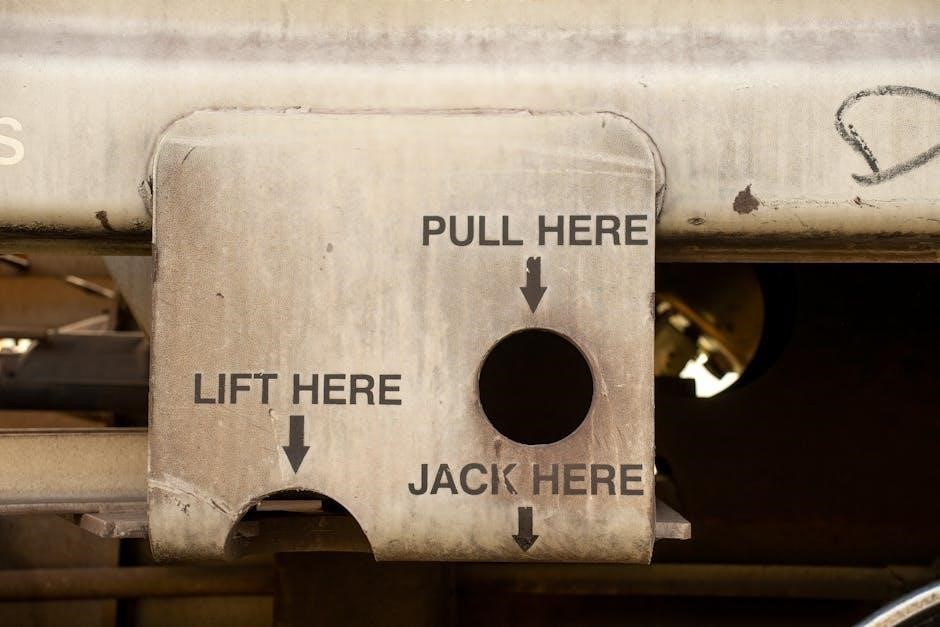

Begin by assessing the load; can you manage it alone, or is team lifting necessary? Plan your route, ensuring a clear path free of obstacles. Position yourself close to the load, with feet shoulder-width apart for a stable base.

Maintain a straight back, bending at the knees and hips, not the waist. Keep the load close to your body throughout the lift. Avoid twisting; pivot your feet instead. Lift smoothly and steadily, using your leg muscles, not your back. Lower the load using the same principles in reverse.

Remember, understanding the risks present during hazardous tasks, as outlined in the MHOR 1992, is crucial for safe lifting practices.

Carrying Techniques

Safe carrying techniques complement proper lifting, minimizing strain and preventing injuries common in manual handling operations. Maintaining a stable posture is key; keep your back straight and your core engaged.

Hold the load close to your body to reduce stress on your spine. Distribute the weight evenly, avoiding uneven loads that can cause imbalance. Keep your shoulders relaxed and avoid hunching.

Take small steps and avoid sudden movements or twisting while carrying. Be aware of your surroundings and potential hazards along your route. If the load obstructs your vision, ask for assistance.

Remember that individuals unaccustomed to lifting or carrying are at higher risk; proper training, as mandated by MHOR, is essential for safe practices and reducing sickness absence.

Team Lifting

Team lifting is crucial when a load exceeds individual capacity or presents an awkward shape, minimizing strain and preventing injuries. Clear communication is paramount; designate one person as the team leader to coordinate movements.

Before lifting, the team must discuss the lifting plan, including the route, potential hazards, and designated grip points. Ensure everyone understands the signals for lifting, lowering, and stopping.

Maintain a synchronized pace and lift together, keeping backs straight and cores engaged. Avoid sudden movements or jerking.

Remember, injuries to the back, shoulders, and neck are significant contributors to workplace absence. Proper training, aligned with MHOR regulations, is vital for safe team lifting practices.

Current State of Legislation (as of 12/04/2025)

Currently, there are no known outstanding effects for The Manual Handling Operations Regulations 1992, remaining stable as of today’s date.

Outstanding Effects on Regulations

As of today, April 12th, 2025, official reports indicate no currently known outstanding effects directly impacting The Manual Handling Operations Regulations 1992. However, the landscape of health and safety legislation is perpetually evolving.

Recent amendments via the Health and Safety (Miscellaneous Amendments) Regulations have been integrated, and employers are expected to demonstrate full compliance with these updates. Ongoing monitoring of European Commission legislation, particularly concerning ground-handling operations, is vital.

While no immediate changes are flagged, proactive organizations should remain vigilant for potential future revisions. Staying informed about emerging best practices and industry standards is crucial for maintaining a safe working environment and adhering to legal obligations regarding manual handling.

Future Legislative Changes (Potential)

Predicting future legislative changes is challenging, but several areas could influence manual handling regulations. Increased focus on ergonomic risk factors and preventative measures is anticipated, potentially leading to more detailed guidance on risk assessment.

Further alignment with evolving European standards, particularly concerning ground-handling operations, remains a possibility. Emphasis on employee health and suitability for tasks, considering pre-existing conditions, may also be strengthened.

Technological advancements, such as the use of assistive devices and automation, could necessitate updates to regulations. Proactive employers should anticipate a continued drive towards minimizing manual handling risks and prioritizing worker well-being through updated legislation.