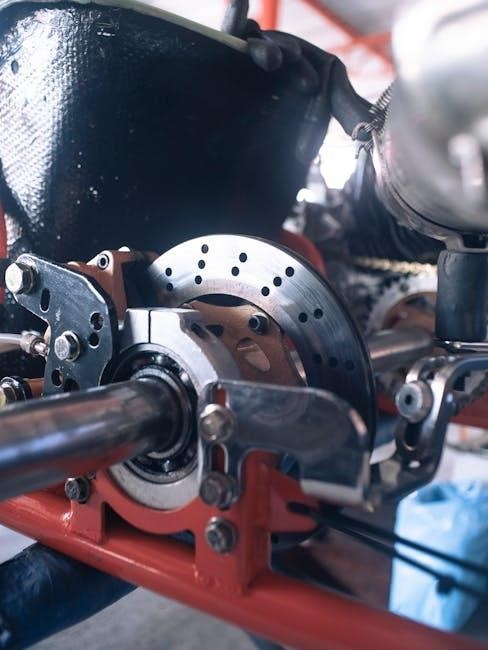

Bolt torque charts provide essential guidelines for tightening bolts to ensure safety and reliability. They help prevent under or overtightening, which can lead to equipment failure; These charts are widely available in PDF formats for easy reference and printing, offering standardized torque values for various bolt sizes, grades, and materials. By following these charts, professionals can achieve precise torque specifications, ensuring optimal performance and longevity of mechanical systems. This guide will explore how to interpret and apply these charts effectively in different applications.

What is a Bolt Torque Chart?

A Bolt Torque Chart is a standardized guide that specifies the recommended torque values for bolts of various sizes, grades, and materials. These charts are essential for ensuring bolts are tightened correctly, preventing under-tightening or over-tightening, which can lead to mechanical failure or damage. Available in PDF formats, they provide a quick reference for engineers and technicians, helping them apply the appropriate torque consistently and safely across different applications. This ensures reliability, performance, and longevity of mechanical systems.

Importance of Using a Bolt Torque Chart

Using a bolt torque chart is crucial for ensuring bolts are tightened to the correct specifications, preventing overtightening or undertightening. Proper torque application ensures safety, reliability, and longevity of mechanical systems. It helps avoid bolt failure, reduces maintenance costs, and minimizes downtime. Torque charts are especially vital in critical applications like engines, construction equipment, and industrial machinery. They provide standardized guidelines, ensuring consistency and accuracy in bolt tightening. By adhering to these charts, professionals can maintain structural integrity and prevent potential hazards. This makes them an indispensable tool in engineering and maintenance tasks.

Understanding Bolt Grades and Materials

Bolt grades (e.g., Grade 2, Grade 5, Grade 8) and materials (steel, stainless steel, bronze) determine strength and torque requirements. Higher grades and specific materials offer greater durability and resistance.

Bolt Grades (Grade 2, Grade 5, Grade 8)

Bolt grades indicate the strength and durability of bolts, with Grade 2 being the lowest and Grade 8 the highest. Grade 2 bolts are suitable for light applications, while Grade 5 offers medium strength, commonly used in automotive and construction. Grade 8 bolts provide the highest strength and are ideal for heavy machinery and critical joints. Each grade has specific torque specifications, ensuring proper tightening without risking damage. Understanding these grades is crucial for selecting the right bolt for your application and ensuring safety and reliability in mechanical systems.

Common Bolt Materials (Steel, Stainless Steel, Bronze)

Bolt materials significantly influence torque values and application suitability. Steel bolts are the most common, offering a balance of strength and cost-effectiveness. Stainless steel bolts provide excellent corrosion resistance, ideal for harsh environments. Bronze bolts are durable and resistant to wear, often used in high-temperature and marine applications. Each material has specific torque recommendations, as outlined in standard bolt torque charts. Understanding the properties of these materials ensures proper bolt selection and optimal performance in various industrial and mechanical systems.

How to Read a Bolt Torque Chart

Reading a bolt torque chart involves identifying bolt size, thread type, and grade. Locate the bolt’s diameter and thread (coarse or fine) on the chart. Match the bolt’s material and grade (e.g., Grade 2, 5, 8) to corresponding torque values. Understand the torque units (inch-pounds or foot-pounds) and adjust for lubrication or dry conditions. Consider environmental factors and plating, which may alter torque specifications. Use conversion factors for bolt conditions like greased or anti-seized. By following these steps, you can accurately determine the correct torque for your application, ensuring safety and reliability.

Identifying Bolt Size and Thread Type

Start by determining the bolt’s diameter, which is listed in the leftmost column of the chart. Next, identify whether the bolt has a coarse or fine thread, as this affects torque values. Coarse-thread bolts have fewer threads per inch, while fine-thread bolts have more, impacting the torque-tension relationship. Ensure the thread type matches the chart’s specifications, as torque values differ between coarse and fine threads. For example, a 1/2″-13 fine thread bolt will have a different torque value than a 1/2″-20 coarse thread bolt. Accurate identification is critical for proper torque application and safety.

Matching Bolt Grade and Material to Torque Values

Once the bolt size and thread type are identified, the next step is to match the bolt grade and material to the corresponding torque values. Bolt grades, such as Grade 2, Grade 5, or Grade 8, indicate the material’s strength, with higher grades requiring higher torque. Materials like steel, stainless steel, or bronze also influence torque specifications. For example, a Grade 8 bolt typically requires more torque than a Grade 2 bolt of the same size. Refer to the chart to find the exact torque value for your specific bolt grade and material combination to ensure proper tightening and avoid damage. This step is crucial for maintaining safety and structural integrity in any application.

Understanding Torque Units (inch-pounds, foot-pounds)

Torque values are typically measured in inch-pounds (in.-lbs.) or foot-pounds (ft.-lbs.). Inch-pounds are commonly used for smaller bolts, while foot-pounds are reserved for larger diameters. It’s essential to use the correct unit of measurement, as using the wrong unit can lead to under or overtightening. For reference, 1 foot-pound equals 12 inch-pounds. Always verify the unit specified in the torque chart to ensure accuracy. Proper understanding of these units is critical for applying the correct torque and maintaining the integrity of the bolted joint.

Factors Affecting Bolt Torque Values

Lubrication, surface finish, thread fit, and plating significantly influence torque values. Environmental conditions and bolt material also play a role in determining accurate torque specifications.

Lubrication and Surface Finish

Lubrication significantly reduces friction between threads, lowering torque values by 25-30%. Surface finish also affects torque; smoother surfaces require less torque due to reduced friction. Dry bolts typically need higher torque, while lubricated ones require less to avoid overtightening. Plating and coatings further influence torque-tension relationships, as they can alter frictional properties. Proper lubrication and surface preparation are critical for accurate torque application and ensuring bolt reliability in various applications.

Thread Fit and Plating

Thread fit and plating impact torque values by altering frictional properties. Tighter thread fits may require slightly higher torque, while loose fits need less. Plating, such as zinc or chrome, reduces friction, lowering torque requirements. Charts often adjust values for plated bolts, typically reducing torque by 25%. Proper consideration of thread fit and plating ensures accurate torque application, preventing damage or loosening. Always refer to specific charts for plated or specialized bolts to maintain precision and safety in assembly processes.

Environmental and Operational Conditions

Environmental factors like temperature, humidity, and vibration affect bolt torque. High temperatures can reduce material strength, requiring lower torque. Corrosive environments may necessitate specialized coatings, altering friction and torque needs. Operational conditions, such as cyclic loading, also influence torque values. Charts often provide adjustments for these variables, ensuring bolts maintain integrity under diverse conditions. Consulting specific guidelines for environmental and operational extremes is crucial for reliable and safe bolt applications in industrial settings. Proper adjustments prevent failure and ensure long-term performance.

Using the Torque Chart for Specific Applications

Match bolt size, grade, and material to torque values for precise fastening. Adjust for lubrication, thread type, and environmental conditions to ensure safe and reliable connections in any application.

Step-by-Step Guide to Applying Torque Values

Identify the bolt size, grade, and material from the torque chart.

Locate the corresponding torque value in the chart based on these specifications.

Adjust the torque wrench to the recommended value, considering lubrication and thread type.

Apply torque in a crisscross pattern for bolts with multiple fasteners to ensure even tightening.

Verify the torque with a wrench if unsure, especially for critical applications.

Document the applied torque for future reference or maintenance.

This method ensures accuracy and safety, preventing over or under-tightening, which can lead to equipment failure.

Adjustments for Lubricated vs. Dry Bolts

Lubricated bolts require reduced torque values compared to dry bolts due to lower friction. Typically, torque values should be reduced by 25-30% for lubricated bolts. This adjustment ensures proper clamping force without overtightening. For plated bolts, further reductions may apply, as plating can act as a lubricant. Always consult the torque chart for specific adjustments based on bolt material and lubrication conditions to achieve optimal fastening results and prevent damage to the bolt or joined materials.

Common Mistakes to Avoid

Overtightening and undertightening are critical errors that can lead to equipment failure or safety risks. Always refer to the torque chart for precise values to avoid these issues.

Overtightening and Undertightening

Overtightening can damage threads or strip bolts, while undertightening may lead to loose joints and safety hazards. Both mistakes often result from ignoring torque charts or misjudging bolt conditions. Over-torquing exceeds the bolt’s yield strength, causing permanent deformation, while under-torquing fails to achieve the required clamp load. Factors like lubrication and material grade significantly impact torque requirements, making it crucial to consult charts for precise values. Always use a torque wrench and refer to the chart to avoid these common errors, ensuring bolts are tightened safely and effectively within specified limits for optimal performance and reliability.

Ignoring Bolt Material and Grade

Ignoring bolt material and grade can lead to incorrect torque application, causing damage or failure. Different materials like steel, stainless steel, or bronze have varying strength and friction levels, affecting torque requirements. Using the wrong grade, such as Grade 2 instead of Grade 8, can result in insufficient clamp load or overtightening. Always refer to torque charts to match the bolt’s grade and material with the correct torque value. Failing to do so risks thread stripping, joint failure, or compromised safety, and may void warranties or certifications. Proper material and grade identification is essential for reliable results.

Understanding bolt torque charts is crucial for ensuring safety and preventing failure. Always refer to standardized guides to avoid common mistakes and achieve optimal results.

Using a bolt torque chart ensures accurate torque specifications for various bolt sizes, grades, and materials. Identify bolt size and grade, then match to torque values. Lubrication, thread type, and surface finish significantly impact torque requirements. Always consider environmental conditions and adjust values accordingly. Proper torque application prevents overtightening or undertightening, ensuring safety and reliability. Refer to standardized charts for precise guidance, and consult updated resources for the latest specifications and adjustments.

Final Thoughts on Proper Bolt Torque Application

Proper bolt torque application is critical for ensuring structural integrity and operational safety. Always refer to standardized torque charts for precise values, considering factors like bolt grade, material, and lubrication. Avoid over or under-tightening, as this can lead to equipment failure. Regularly update your knowledge with the latest specifications and adjustments for optimal results. By following these guidelines, you ensure reliability, durability, and safety in all mechanical applications.